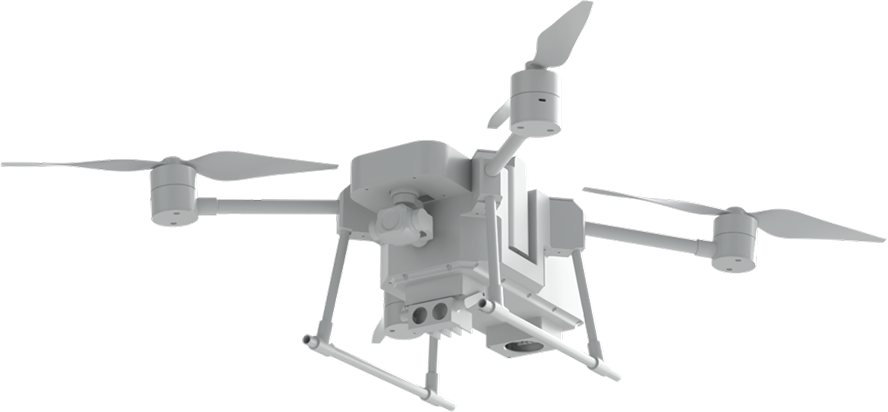

Advanced vision systems for quality control and production automation

Discover the Quality Assurance systems developed by Falcon Drones engineers. Powered by AI algorithms, our solutions are error-resistant, better suited for demanding conditions, and ready for seamless integration with your organization’s IT systems.

Quality Assurance (QA) systems

Falcon Drones offers comprehensive services in the development of vision systems, with a strong focus on Quality Assurance (QA) systems and production automation.

Our solutions help improve production quality while reducing costs and increasing control efficiency. By implementing camera-based systems, you can eliminate errors and minimize losses caused by production defects.

Tailor-made vision solutions

What does the system provide you with?

AI-based image processing algorithm

The system analyzes images in real time and presents the results in a clear way, for example, on a display screen or via a visual signal indicator.

Integration with existing IT systems

System output, such as reports, can be sent directly to a production management system or a specified database.

Hardware selection

Falcon Drones engineers will select a camera suitable for the installation site. They will also support the mounting process and prepare the necessary structure for the system.

Reliable operation and support

All our systems come with a warranty and after-sales service. They are also open to further expansion and the implementation of additional features in the future.

How can vision systems support your production?

Falcon Drones specialists develop image processing and analysis tools designed to operate even in the most challenging conditions. Discover the full potential of our systems:

Quality Assurance

Verify assembly accuracy, detect defects and imperfections that should not occur during manufacturing or assembly processes.

Detection of production errors and omissions

Use our systems to identify errors and missing components along the production line.

Automatic reading of barcodes, QR codes, and other product labels

Benefit from automated product batch assignment, production process tracking, and logging of product-related data.

Tailor-made systems for every industry

Would you like to find out if your production processes can be optimized using vision systems? Contact us for a free audit.